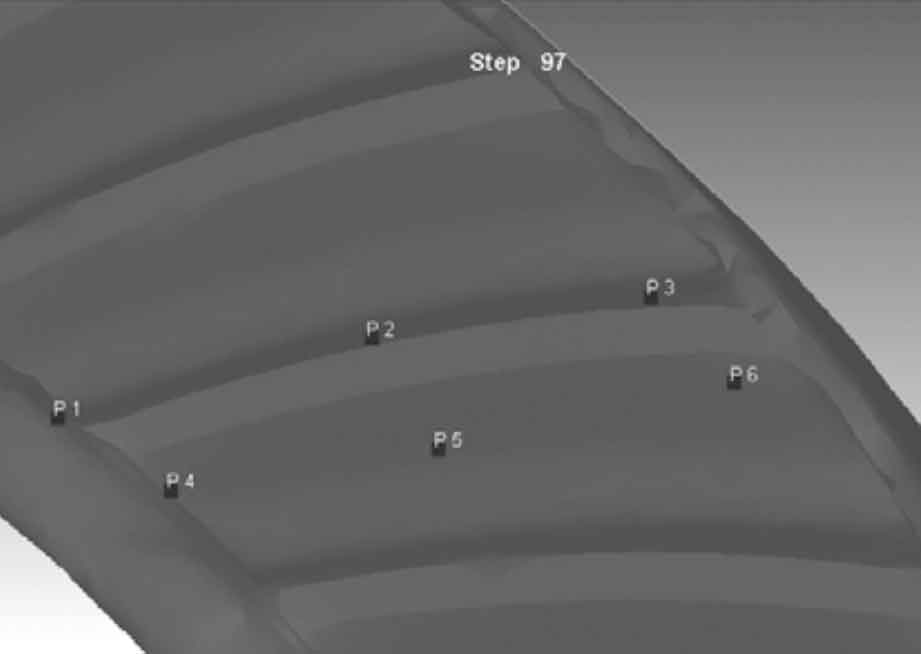

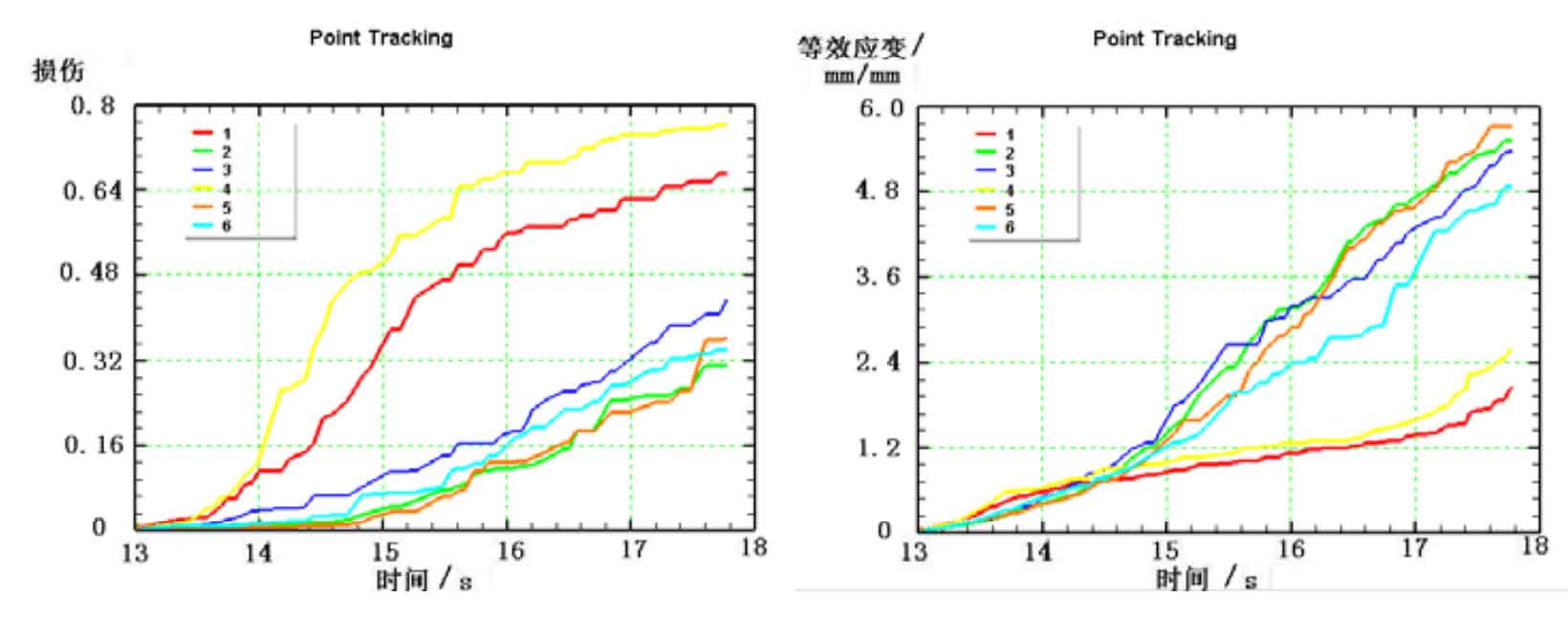

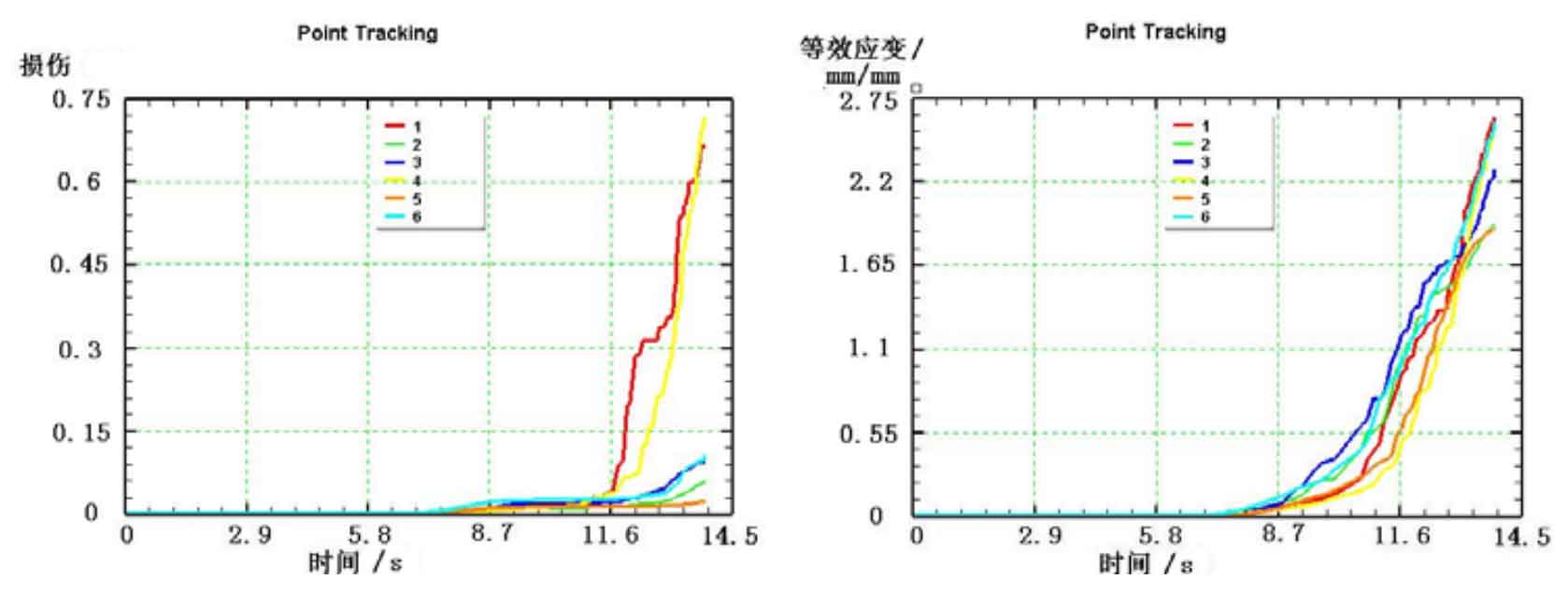

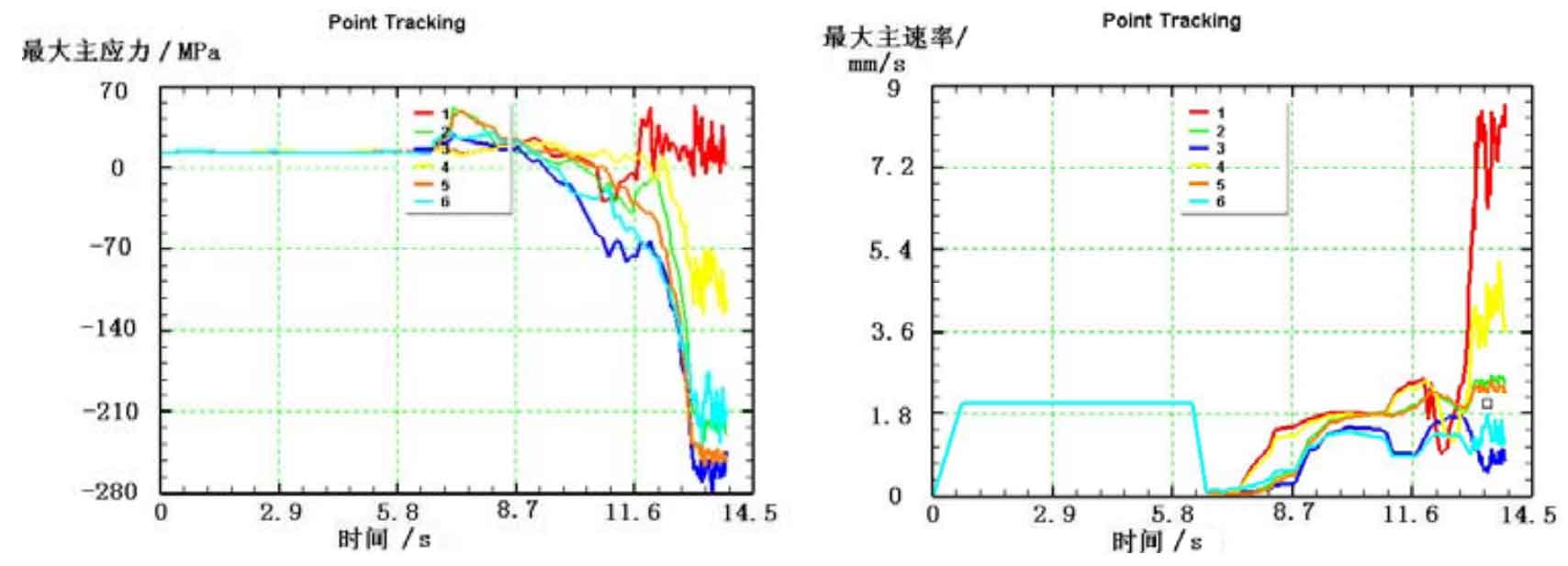

Six points are selected on the tooth surface. Points P1 ~ P3 correspond to three positions on the convex surface of the tooth from the small end to the large end of the tooth, and points P4 ~ P6 correspond to three positions on the concave surface of the tooth from the small end to the large end of the tooth. Their positions are shown in Fig. 1, and the damage results at six points on the tooth surface are shown in Fig. 2.

(b) 6-point equal effect variation diagram of tooth surface – hot forging

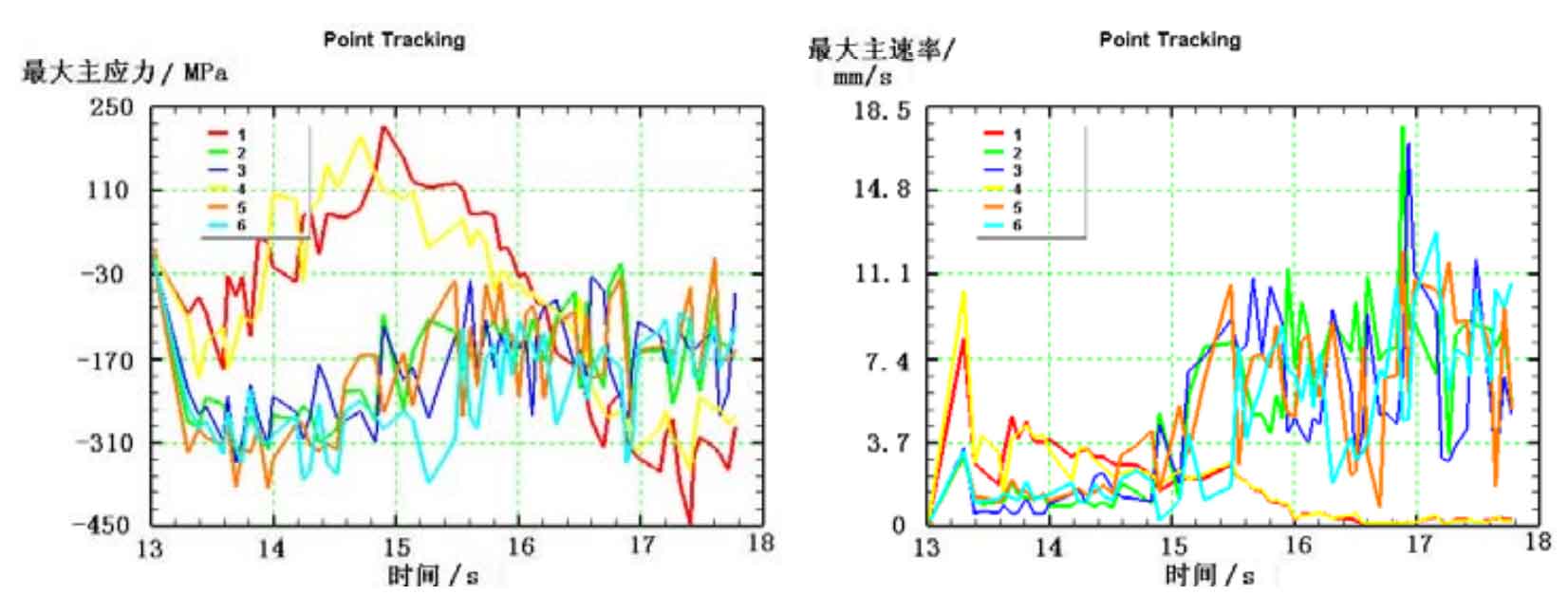

(d) Maximum principal velocity diagram of tooth surface at 6 points – hot forging