0 Introduction

The arc bevel gear adopts shrinking teeth, and the tooth line on the gear production crown wheel is an arc, so the arc bevel gear transmission is stable, low noise, and the bearing capacity is higher than that of straight bevel gear, which has the characteristics of easy control and adjustment of tooth surface contact area, and is not very sensitive to installation errors and deformation. It is suitable for intersecting shaft gear transmission with circumferential speed v>5m/s or speed n>1000r/min, and heavy-duty transmission.Nowadays, arc bevel gears are increasingly used in wells and various drilling rigs to replace straight bevel gears. Drilling rigs are often used in transmission boxes, transfer cases or turntables, and the shaft angle Σ=90° has special requirements When calculating, Σ≠90° is allowed, and the spiral angle is generally β=35°.

Arc bevel gear transmission has the advantages of large coincidence coefficient, stable transmission, high bearing capacity, long service life and large transmission ratio, which is widely used in space transmission in aviation, aerospace and automotive mechanical transmission systems, and the domestic mining, metallurgy, cement, petroleum and shipbuilding industries have gradually adopted arc bevel gears with higher and higher precision. China began to use arc tooth bevel gears from the mid-60s of the 20th century Relevant research has been carried out, with the improvement of the development level of the domestic manufacturing industry, CNC gear milling machine is gradually popularized, and the design, production and manufacturing cost of arc bevel gear pair under high-speed and heavy-duty conditions are getting lower and lower. The gear pair also meets the relevant requirements in the field of geological drilling in terms of relative motion, lubrication, transmission efficiency, bearing capacity, vibration and noise, energy saving and high efficiency. The application of arc bevel gears in geological drilling machinery began to show an upward trend, especially in the gearbox, transfer case, winch, turntable and other system components of the drilling rig. This article takes the 600 m water well drilling rig gearbox commonly seen in the current market as an example to discuss the design of arc bevel gear in drilling rigs.

1 Preliminary calculation of the main parameters of arc bevel gear

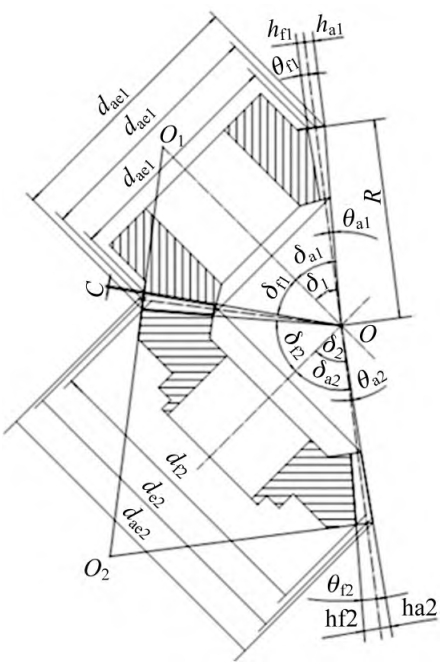

According to the transmission requirements, the shaft angle Σ=90°, the helix angle β=35°, the initial value of the number of teeth ratio u0=1.3, the small wheel torque T1 is calculated according to 4000N·m, the initial value of the large end of the small wheel is d10 =190 mm, the pinion is left-handed, the big gear is right-handed, and the design diagram is shown in Figure 1.

Figure 1 Design drawing of arc bevel gear

Preliminary selection of the number of teeth of small wheel gear z1=27; The number of large wheel teeth z2=u0×z1=35.1, and the number of large wheel teeth z2=35 after rounding; Large end surface modulus mt=d10/z1=7mm; According to the selected Gleason tooth shape, the tooth top height coefficient ha = 0.85, the top clearance coefficient c = 0.188, and the normal pressure angle αn=20°; Working tooth height h′=2h*a mt=11.9mm; tangential displacement coefficient xn=0.

2 Calculation of geometric parameters of arc bevel gears

Arc bevel gear is based on the evolution of spur bevel gear, meshing area is greater than spur bevel gear, considering the strength factor, the same material and heat treatment method and processing accuracy, as well as the same end face modulus

and related geometric parameters such as the number of teeth. Combined with the working conditions in the field of geological drilling, medium-load gears with high speed or heavy-duty gears with medium speeds are required, and 7 levels of accuracy with higher accuracy levels are specially selected.

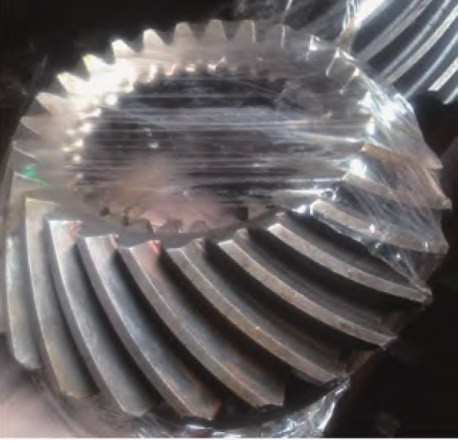

The geometric parameters of the arc bevel gear are calculated as follows, and the actual processing diagram is shown in Figure 2.

Figure 2 Actual machined arc bevel gear

Small wheel large end indexing circle diameter de1=MTZ1=189mm; Large wheel large end indexing circle diameter de2=MTZ2=245mm.

The wheel cone angle δ1 is calculated by:δ1 =arctan[sinΣ ÷ (z2/z1 +cosΣ)] (1)

The calculation yields δ1 =37.6476°=37°38′51″; The cone angle δ2=90°-δ1=52°21′9″.

The large end cone pitch R=de1/(2sinδ1)=154.714mm, tooth width b=0.3R=46.414 mm, and the large end tooth pitch p=πmt =21.9911mm. Top height ha=(h*

A + XN)mt=5.95mm, tooth top clearance

c=c* mt=1.316mm, root height hf=(h*

a +c* )mt=

7.266mm, full tooth height h=ha+hf=13.216mm. The equation [1] for tooth root angle θf is θf = arctan(hf/R) (2)

Calculated θf = 2°41′20″

Small wheel top cone angle δa1=δ1+θf=40°20′11″, large wheel top cone angle

δa2=δ2+θf=55°2′29″。 The angle of the small wheel root cone δf1 = δ1 -θf=34°57′31″, and the angle of the large wheel top cone δf2=δ2-θf=49°39′49″.

Small wheel tooth top circle diameter da1 = de1 + 2hacosδ1 =

198.4222 mm, large wheel tooth top circle straight diameter da2 = de2 +2hacosδ2 = 252.2686mm.

The calculation formulas of Aa1 and Aa2 for small and large crown top distances [1] are respectively

Aa1 =de2/2-hasinδ1 (3)

Aa2 =de1/2-hasinδ2 (4)

The calculation yields Aa1=118.8657mm and Aa2=89.7889mm.

The formula [1] for calculating the thickness of the index arc tooth [1] is

s=mt(π/2+2xntanαn +xn) (5)

The calculation yields s=10.996mm.

3 Practical application

The arc gears machined according to the above parameters are used in the SP-600 drilling gearbox to replace the original spur bevel gears. During the running-in test, it was found that the transmission was stable and the noise was significantly reduced. In the construction of Laiyuan Water Well Project, the drilling depth was 400m, and the diameter of the final hole was 311mm; In a water well construction project in Qinghai, the drilling depth was 450m, and the diameter of the final hole was 273mm. Users generally report that the gearbox is working properly,

Low noise and approx. 30% higher drilling efficiency. After the 10000h wear resistance application experiment, the wear degree of arc bevel gear is significantly reduced compared with the straight bevel gear, and the purpose of extending the service life of bevel gear is achieved, and the application effect is shown in Figure 3.

Figure 3 Using an arc-toothed bevel gear after 10000h

Bearing heavy load drilling rig gearbox and turntable bevel gear pair has always been a vulnerable part of the drilling rig, seriously affecting the normal operation of the drilling rig, after the use of arc bevel gear pair transmission with large coincidence coefficient, the transmission is more stable, the impact load bearing capacity is significantly improved, the service life is increased, and now the arc

Bevel gears have been widely used in drilling gearboxes and partial turntables in deep and medium holes.

4 Conclusion

With the development and transformation of the geological survey industry, construction units have higher and higher requirements for drilling rig efficiency and drilling equipment stability. The drilling rig using arc bevel gear transmission improves the stability of drilling equipment, meets the requirements of the construction unit for equipment, and is also of great significance to the improvement of drilling equipment.