Selecting the right spur gear for automotive applications is critical due to the specific demands of vehicle performance, durability, and efficiency. Here’s a comprehensive guide on how to choose the appropriate spur gear for automotive use:

1. Material Selection

- Steel Alloys: Most commonly used in automotive applications due to their high strength and durability. Alloys like AISI 4340, 4140, and 8620 are popular for their wear resistance and ability to withstand high stress.

- Advanced Treatments: Consider spur gear that have undergone advanced heat treatments such as case hardening, nitriding, or carburizing to enhance surface hardness and fatigue resistance.

- Lightweight Materials: In applications where weight reduction is crucial, such as in racing or electric vehicles, consider materials like aluminum or titanium alloys.

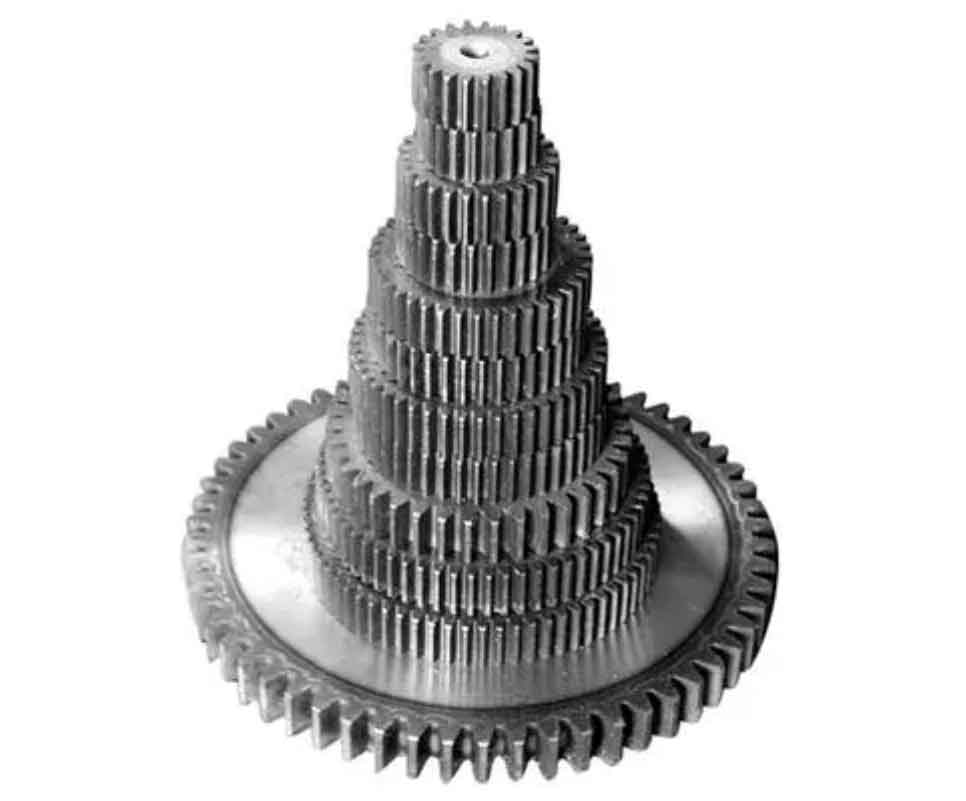

2. Gear Design

- Tooth Profile: The standard involute tooth profile is typically used because it offers smooth and efficient power transmission. Modifications like profile shifting or adding tip relief can be made to optimize load distribution and minimize stress concentrations.

- Size and Dimensions: Ensure spur gear dimensions meet the specific torque and space requirements of the automotive application. This includes selecting the correct pitch, face width, and diameter.

- Noise Reduction: In passenger vehicles, minimizing noise is crucial. Opt for gears with fine pitch, or consider helical gears if noise reduction is a priority and space allows.

3. Load Capacity

- Torque Requirements: Analyze the maximum torque requirements of the automotive application. Spur gear must be capable of handling peak loads without risk of failure.

- Safety Factors: Apply appropriate safety factors when calculating load capacities to account for unexpected stresses and to ensure longevity.

4. Lubrication

- Lubricant Type: Select a lubricant that can withstand the temperature and pressure conditions expected in automotive applications. Synthetic lubricants are often preferred for their better performance across a wide range of temperatures and reduced friction.

- Lubrication System: Consider the integration of an effective lubrication system that ensures consistent and adequate lubrication, especially in high-performance or heavy-duty applications.

5. Efficiency and Performance

- Gear Efficiency: Evaluate the efficiency of spur gear design. Higher efficiency gears contribute to better fuel economy and lower energy consumption in electric vehicles.

- Dynamic Performance: Consider the dynamic performance of spur gear, including its ability to operate smoothly at high speeds and under varying load conditions.

6. Manufacturing Process

- Precision Machining: Ensure that spur gear is manufactured using high-precision machining techniques to achieve tight tolerances and high-quality finishes.

- Quality Control: Choose manufacturers with robust quality control processes to avoid defects such as misalignments or surface imperfections that can lead to premature wear or failure.

7. Environmental Factors

- Temperature and Conditions: Assess the environmental conditions spur gear will be exposed to, including temperature extremes and potential contaminants like dust or chemicals.

- Corrosion Resistance: For spur gear exposed to corrosive environments, consider corrosion-resistant materials or coatings.

8. Regulatory and Compliance Issues

- Standards Compliance: Ensure spur gear design and materials comply with automotive industry standards and regulations, including those for safety and emissions where applicable.

Conclusion

Choosing the right spur gear for automotive applications involves a careful analysis of material properties, gear design, load capacities, and environmental factors. By addressing these elements, manufacturers can ensure that the selected gears provide the required performance, durability, and reliability for automotive use.