The research shows that the contact and bending stresses of spur gears can be obtained by finite element method, and the tooth surface coordinates of spur gears can be determined by analytical solution, and these coordinate values can be input into the finite element analysis software. However, for hypoid gears, there is no explicit formula to express the coordinates of tooth surface points. The difference between hypoid gear and spiral bevel gear is that there is an offset moment between the cross shafts of the two gears. Many research results of spiral bevel gear can be used for reference. Many scholars at home and abroad have studied spiral bevel gear modeling, but these models have the following shortcomings:

First, there are differences between the established model and the actual machine tool structure. The current model does not give a detailed correlation between the theoretical model and the actual machine tool structure.

Second, there are difficulties in solving the model. Because the coordinate equation of hypoid gear tooth surface is a nonlinear equation, and the solution of the nonlinear equation is related to the initial value, there is no method to take the initial value and solve it at present. Therefore, the calculation method of tooth root bending stress of hypoid gear based on finite element has not been widely used.

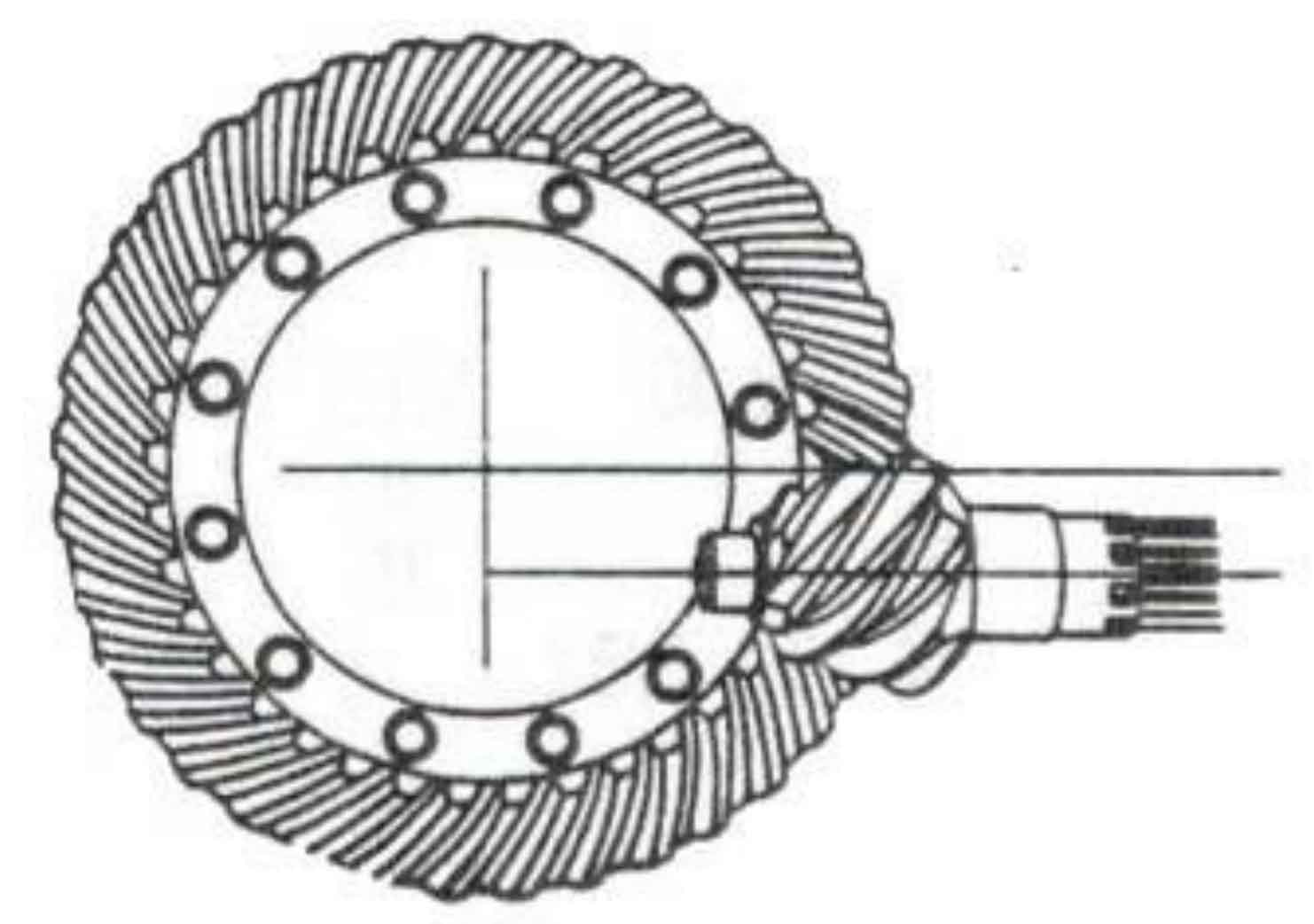

The purpose of this study is to establish a mathematical model to obtain the surface points of spiral tooth hypoid gears to simulate the widely used gleason#116 spiral tooth hypoid gear machining process. Firstly, the gear machining process is analyzed in depth before the gear modeling. In the process of mathematical modeling, the coordinates of tooth surface points are obtained by using the machine parameters of the machining machine tool and the basic design parameters of the gear blank, and the convex and concave surfaces of the gear are obtained. Then rotate the tooth surface to get a complete gear tooth surface, and design the calculation program surf, which can automatically calculate the coordinates of the tooth surface points. Finally, taking a hypoid gear as an example, the coordinates of tooth surface points are obtained by using the calculation program, and the coordinates of tooth surface points are imported into CATIA to obtain the three-dimensional solid model of the gear.