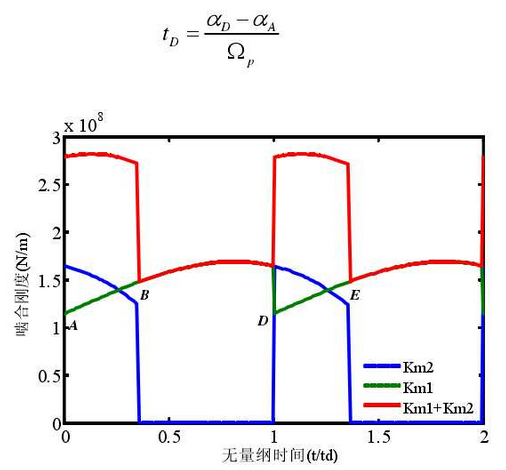

The fluctuation of gear meshing stiffness is an important excitation source for gear vibration. Accurate calculation of gear meshing stiffness is conducive to retaining the information of actual tooth profile characteristics and facilitating experimental verification.Firstly, the time-varying meshing stiffness as the deployment angle changes is calculated, and the instantaneous stiffness of two teeth meshing at the same time is defined according to the timing of rodenting:

As shown.For ease of analysis, the transverse coordinates are represented by dimensionless time (t/tD), dimensionless time (t/tD) and dimensionless time (t/tD). Where D t is the time that a gear meshing point passes through a pitch after being meshed in, it can be calculated as follows:

The variation of the actual friction arm can be calculated according to the formula as shown in the figure.It can be seen that the sum of the two force arms of the active gear engaged in meshing is equal to that of the passive gear. The value is 17.629mm of the engagement line length. The force arm of the active gear increases periodically with rotation while the force arm of the passive gear decreases periodically.