Introduction

With the development of the times, cars have become an essential household item, but as the use time increases, car gears will wear to varying degrees, especially the rear axle spiral bevel gear. This is due to the coupling vertical vibration of the rear axle during the driving process, which leads to wear of the rear axle spiral bevel gear. If not detected in time, it will reduce the safety of car driving Damage detection methods improve the accuracy of gear wear detection, enhance the safety of vehicle driving, and provide security for people’s transportation.

Based on the wavelet packet energy and modulation signal bispectrum sideband estimation method for gear wear detection, the gear wear signal is decomposed into multiple frequency bands using wavelet packet transform, and then the tooth surface wear characteristics are extracted from the wear signal using the modulation signal bispectrum sideband estimation method. Finally, the gear wear detection is completed through the detection index. However, this method does not consider the interference of noise, resulting in insufficient accuracy in gear wear detection. A gear wear detection method based on reverse engineering is proposed. This method is based on the principle of gear wear detection, constructs a transformation matrix for the wear area of the gear, and performs error compensation for the wear area. Combined with the compensation points, a NURBS surface fitting equation is constructed to complete the detection of gear wear. However, the fitting result of the wear surface in this method may appear non-wear areas, resulting in insufficient detection effect. A gear wear detection method based on improved MaskScoringRCNN is proposed. This method uses residual networks and feature pyramid networks as the backbone network to extract gear wear features through semantic information and detail feature fusion. After normalizing the local feature layer, the binary mask graph information is calculated to complete the detection of gear wear. However, this method does not consider data denoising, resulting in excessive noise in the sample data, which reduces the detection accuracy of gear wear. In order to solve the problems existing in the above gear wear detection methods, a Delaunay triangulation method for automotive spiral bevel gear wear detection is proposed. Using Delaunay triangulation to process adjacent scan lines of discrete data on the tooth surface, non-characteristic discrete data blocks on the tooth surface are completed. Using Hermite interpolation algorithm to traverse and detect the divided Delaunay triangular mesh, gear wear detection is completed.

Non-characteristic discrete data partitioning of tooth surface

The surface of the spiral bevel gear model of the car is constructed, and the surface data is non-characteristicly segmented using Delaunay triangulation. No other points exist within the circumcircle of any triangle in the triangular mesh, and triangles are formed with the nearest point, regardless of where on the tooth surface they begin

Applying Delaunay triangulation to the segmentation of non-characteristic data on the tooth surface can accurately describe the region of the automotive spiral bevel gear surface, which can help improve the detection accuracy of gear wear.

Select the central triangle with the smallest area value as the starting triangle, as shown in the figure. Select the adjacent triangle with the smallest angle with the starting triangle as the central triangle. If the equation is satisfied, then exclude the starting central triangle. Calculate the angle between the surrounding triangles and the starting triangle, and take the triangle with the smallest angle as the central triangle. Otherwise, continue to reselect the starting triangle.

Experimental analysis

In order to verify the effectiveness of the Delaunay triangulation method for wear detection of automotive spiral bevel gears, a comparative testing experiment was conducted. In this study, the spiral bevel gears of a 2015 Santana manual car were selected as the research object, and 20 identical gears were selected for study. The spiral bevel gears are stable in operation, have a large transmission ratio, transfer high power, and are compact in structure, which can meet the needs of this experiment.

Based on the experimental equipment and material attribute data described above, the experimental process was planned in order to obtain more accurate experimental results. The specific experimental process is as follows:

(1) Keep the gear wear experimental equipment running continuously for 200 hours, collect the wear data of the gear within 200 hours, and the data collection interval is 5 minutes. 12 sets of wear data can be collected within one hour.

(2) Set the gear wear depth, gear wear rate, and wear area detection accuracy as the test indicators for this experiment.The proposed detection method based on reverse engineering and the proposed detection method based on improved MaskScoringR-CNN were used as the comparison methods for this experiment.

(4) According to the set experimental indicators, three different methods were used for experimental verification.

Gear wear depth

Gear wear is mainly caused by the wear between the driving gear and the driven gear. The wear depth of the gear varies with the increase of operating time. The wear depth results of the driving gear and the driven gear show that the wear depth of 0 is the initial surface state, and the position with higher gear wear degree is the tooth top and root. Comparing the wear depth detection results of the three methods with the actual results, it is found that the wear depth results of the studied methods are basically consistent with the actual measurements, but there is a large difference between the wear depth values of the methods and the actual measurement results. Therefore, it shows that the studied method can effectively analyze the wear depth of gears.

Gear wear rate

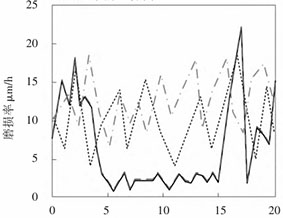

Gear wear rate refers to the amount of wear of gear material per unit time, which can effectively reflect the wear condition of the gear. Therefore, the wear rate detection results of the three methods were also compared and analyzed with the actual wear rate measurement results.

The comparison results of gear wear rates show that in the process of studying 20 gears, the wear rates of the studied methods are always consistent with the actual wear rates, with a maximum error of no more than 0.01μm, while the wear rates of the methods differ significantly from the actual wear rates. Therefore, it is shown that the studied method can obtain more accurate gear wear rate results and improve the detection effect of gear wear.

Detection accuracy of gear wear area

In order to further verify the gear wear detection performance of the proposed method, a comparison was conducted using the area detection accuracy of the gear wear area as an indicator. The wear area of 20 gears was detected in each experiment, and a total of 10 experiments were conducted. The wear area detection in each experiment was The value results. From the comparison results of the gear wear area detection accuracy, it can be seen that the wear area detection accuracy of the research method reaches a maximum of 98.7%, while the maximum values of the two comparison methods are 79.4% and 84.3%, respectively. Therefore, it is shown that the research method can accurately detect the area of the gear wear area.

Conclusion

The detection of wear on automotive spiral bevel gears is beneficial to the safety of car driving and has great practical significance for the safe and stable operation of cars. Therefore, a Delaunay triangulation method for detecting wear on automotive spiral bevel gears is proposed. The adjacent scanning lines on the tooth surface are Delaunay triangulated to complete the segmentation of non-characteristic discrete data on the tooth surface. Based on the segmentation results, Hermite interpolation is used to calculate the replication of the PF component, and all triangular meshes are traversed to complete the detection of wear areas. The data shows that the wear depth and wear rate results of the proposed method are basically consistent with the actual values, and can accurately detect the area of the wear area, with a maximum detection accuracy of 98.7%. It effectively solves the problems existing in traditional methods and injects fresh blood into automotive spiral bevel gear wear detection technology.