Characteristics, Applications, Functions, and Limitations

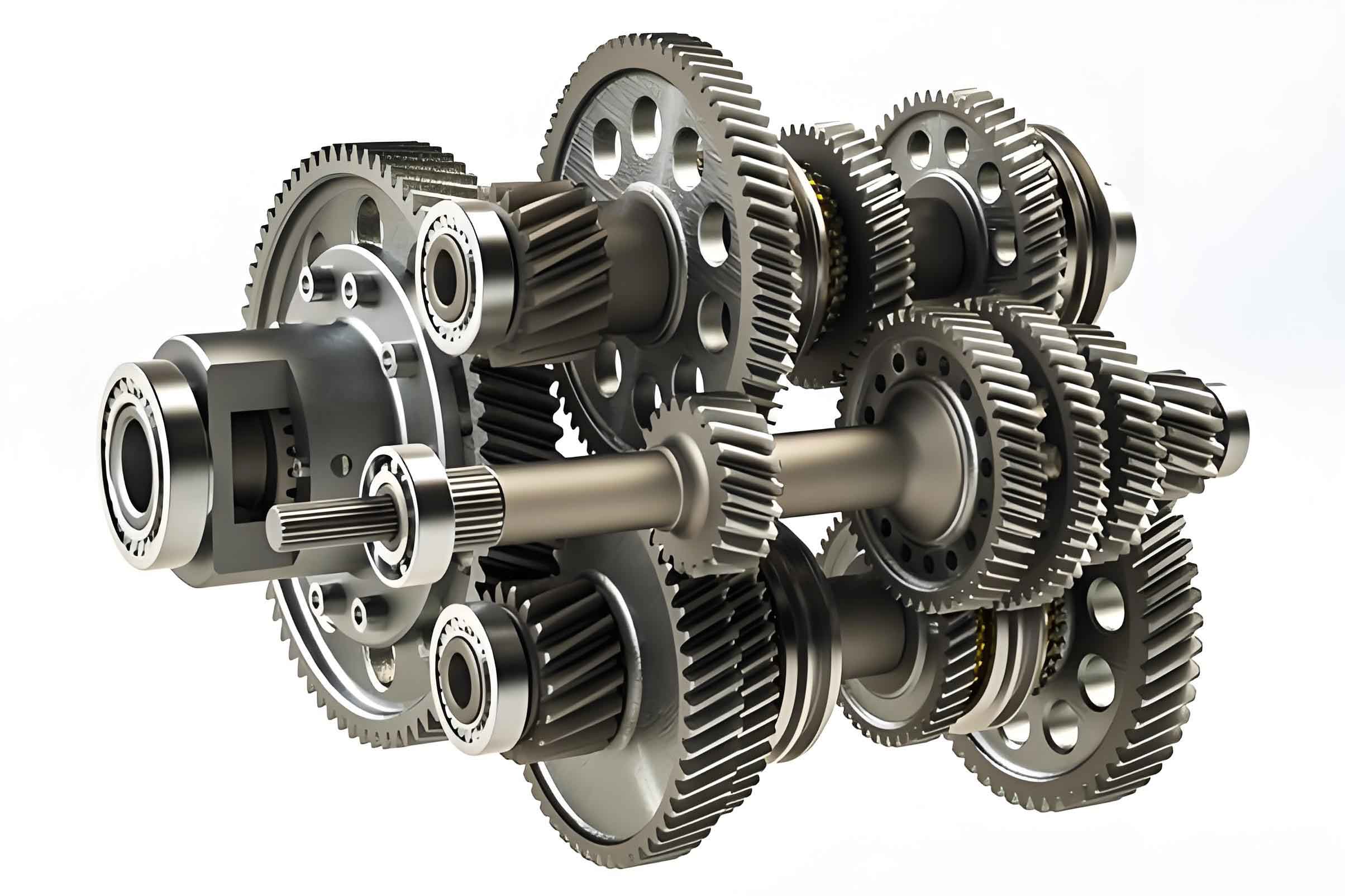

Spiral bevel gears are an essential component in various mechanical systems, particularly in the field of power transmission. They possess unique characteristics that make them suitable for a wide range of applications, while also presenting certain limitations that need to be considered during their design and use.

One of the key features of spiral bevel gears is their ability to transmit power smoothly and efficiently. Due to their design, they can handle high loads and speeds, making them ideal for use in applications where power and torque need to be transferred reliably. These gears are widely used in the central transmission system of aircraft engines, as they play a crucial role in transferring power from the engine to other components of the aircraft.

The design of spiral bevel gears allows for a more even distribution of load across the gear teeth, reducing wear and increasing the lifespan of the gear. This is particularly important in applications where the gear is subjected to continuous operation and high stresses. Additionally, the spiral shape of the teeth helps to reduce noise and vibration during operation, contributing to a smoother and more stable performance of the mechanical system.

In terms of applications, spiral bevel gears can be found in a variety of industries. In the aerospace industry, as mentioned earlier, they are used in the central transmission system of aircraft engines to ensure the efficient transfer of power. In the automotive industry, they are used in differentials and transmissions to provide the necessary power and torque to the wheels. They are also used in industrial machinery, such as pumps, compressors, and conveyor systems, where reliable power transmission is essential.

The function of spiral bevel gears is to change the direction and speed of rotation, allowing for the transfer of power between shafts that are not aligned. This makes them an indispensable component in many mechanical systems, as they enable the efficient operation of complex machinery.

However, like any mechanical component, spiral bevel gears also have some limitations. One of the main challenges is the complexity of their design and manufacturing process. Producing high-quality spiral bevel gears requires precise machining and manufacturing techniques, which can increase the cost and time required for production.

Another limitation is related to the potential for failure. As shown in the analysis of a certain type of central transmission, during the commissioning test, the active spiral bevel gear experienced tooth fracture failure. The macro inspection of the failed spiral bevel gear revealed that the contact mark of the entire circumference of the active spiral bevel gear was uneven, biased towards the small end and close to the tooth bottom. The contact mark of the driven spiral bevel gear was distributed at the top of the small end teeth, and the mark was incomplete and partially exceeded the working surface.

The fracture analysis of the failed active spiral bevel gear showed that the fracture was caused by high-cycle fatigue. The fatigue originated from the corner between the small end face and the convex root of the tooth. Further analysis indicated that the main reason for the early fatigue cracking of the gear was the abnormal occlusion during the working process. This suggests that the design and processing parameters of the gear need to be optimized to ensure a better meshing quality during operation and reduce the risk of failure.

To better understand the performance and behavior of spiral bevel gears, various tests and analyses are conducted. For example, in the case of the failed gear, a wide range of means were utilized, including surface appearance inspection, fractographic analysis, metallographic examination, hardness testing, and composition analysis. In addition, simulation and verification of the contact pattern were conducted to determine the failure modes and causes.

The results of these analyses can be presented in the form of charts and graphs. For instance, the macro morphology of the failed gear can be illustrated in a figure, showing the location and extent of the damage. The fractographic analysis can be presented using scanning electron microscope images, showing the fatigue arcs and radial ridges on the fracture surface. The hardness test results can be presented in a graph, showing the hardness distribution across different parts of the gear.

In conclusion, spiral bevel gears play a vital role in power transmission systems, but their design, manufacturing, and usage require careful consideration to ensure their reliability and performance. By understanding their characteristics, applications, functions, and limitations, engineers can make informed decisions when selecting and using these gears in various mechanical systems. Continued research and development in this field are essential to further improve the design and performance of spiral bevel gears and to address the challenges associated with their use.

Spiral bevel gears are an essential component in various mechanical systems, particularly in the field of power transmission. They possess unique characteristics that make them suitable for a wide range of applications, while also presenting certain limitations that need to be considered during their design and use.

One of the key features of spiral bevel gears is their ability to transmit power smoothly and efficiently. Due to their design, they can handle high loads and speeds, making them ideal for use in applications where power and torque need to be transferred reliably. These gears are widely used in the central transmission system of aircraft engines, as they play a crucial role in transferring power from the engine to other components of the aircraft.

The design of spiral bevel gears allows for a more even distribution of load across the gear teeth, reducing wear and increasing the lifespan of the gear. This is particularly important in applications where the gear is subjected to continuous operation and high stresses. Additionally, the spiral shape of the teeth helps to reduce noise and vibration during operation, contributing to a smoother and more stable performance of the mechanical system.

The working principle of spiral bevel gears is based on the meshing of their teeth. When two spiral bevel gears are engaged, the teeth of one gear interact with the teeth of the other gear, transferring torque and motion. The spiral shape of the teeth allows for a gradual and smooth engagement, which helps to reduce shock and wear. The angle of the teeth and the geometry of the gears are designed to ensure efficient power transmission and proper alignment of the shafts.

In terms of applications, spiral bevel gears can be found in a variety of industries. In the aerospace industry, as mentioned earlier, they are used in the central transmission system of aircraft engines to ensure the efficient transfer of power. In the automotive industry, they are used in differentials and transmissions to provide the necessary power and torque to the wheels. They are also used in industrial machinery, such as pumps, compressors, and conveyor systems, where reliable power transmission is essential.

The function of spiral bevel gears is to change the direction and speed of rotation, allowing for the transfer of power between shafts that are not aligned. This makes them an indispensable component in many mechanical systems, as they enable the efficient operation of complex machinery.

However, like any mechanical component, spiral bevel gears also have some limitations. One of the main challenges is the complexity of their design and manufacturing process. Producing high-quality spiral bevel gears requires precise machining and manufacturing techniques, which can increase the cost and time required for production.

Another limitation is related to the potential for failure. As shown in the analysis of a certain type of central transmission, during the commissioning test, the active spiral bevel gear experienced tooth fracture failure. The macro inspection of the failed spiral bevel gear revealed that the contact mark of the entire circumference of the active spiral bevel gear was uneven, biased towards the small end and close to the tooth bottom. The contact mark of the driven spiral bevel gear was distributed at the top of the small end teeth, and the mark was incomplete and partially exceeded the working surface.

The fracture analysis of the failed active spiral bevel gear showed that the fracture was caused by high-cycle fatigue. The fatigue originated from the corner between the small end face and the convex root of the tooth. Further analysis indicated that the main reason for the early fatigue cracking of the gear was the abnormal occlusion during the working process. This suggests that the design and processing parameters of the gear need to be optimized to ensure a better meshing quality during operation and reduce the risk of failure.

To better understand the performance and behavior of spiral bevel gears, various tests and analyses are conducted. For example, in the case of the failed gear, a wide range of means were utilized, including surface appearance inspection, fractographic analysis, metallographic examination, hardness testing, and composition analysis. In addition, simulation and verification of the contact pattern were conducted to determine the failure modes and causes.

The results of these analyses can be presented in the form of charts and graphs. For instance, the macro morphology of the failed gear can be illustrated in a figure, showing the location and extent of the damage. The fractographic analysis can be presented using scanning electron microscope images, showing the fatigue arcs and radial ridges on the fracture surface. The hardness test results can be presented in a graph, showing the hardness distribution across different parts of the gear.

In conclusion, spiral bevel gears play a vital role in power transmission systems, but their design, manufacturing, and usage require careful consideration to ensure their reliability and performance. By understanding their characteristics, applications, functions, and limitations, engineers can make informed decisions when selecting and using these gears in various mechanical systems. Continued research and development in this field are essential to further improve the design and performance of spiral bevel gears and to address the challenges associated with their use.