Due to the advantages of low-pressure vacuum carburizing and high-pressure gas quenching heat treatment in terms of carburizing accuracy, intergranular oxidation control, and deformation control of parts compared to traditional atmosphere carburizing, they have been widely used in the fields of automotive parts manufacturing, machinery, and aerospace parts manufacturing. The speed of the transmission system of new energy vehicles has increased significantly compared to traditional fuel vehicles, reaching tens of thousands of revolutions per minute. Therefore, higher requirements have been placed on the accuracy and reliability of key components such as gears and bearings for new energy vehicles. An imported multi-heating chamber automated vacuum low-pressure carburizing production line is mainly used for the production of precision gears for new energy vehicles in the factory. The attached Infracarb process simulation system can simulate the number and duration of strong infiltration and diffusion pulses based on the material and effective hardened layer depth requirements of the processed workpiece. Based on the differences in hardenability and quenching process of the materials used in production workpieces, the effective hardened layer depth detection results are within 5% of the simulated values.

Heat treatment production and testing

The material used for the gear workpiece is 20CrMnTiH steel.

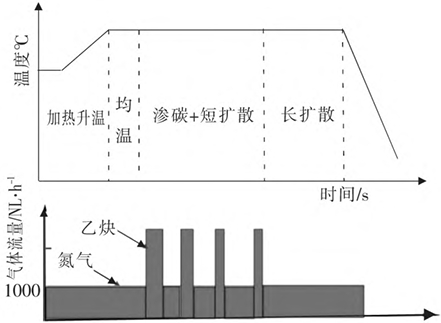

Vacuum low-pressure carburizing + high-pressure gas quenching heat treatment process

The heat treatment of 20CrMnTiH steel gears is carried out using vacuum low-pressure carburizing and high-pressure gas quenching. The low-pressure carburizing includes multi-pulse strong carburizing (introducing high-purity acetylene) and diffusion (equilibrium gas high-purity nitrogen).

After the steel gear is carburized, it undergoes a high-pressure quenching process at 15-20 bar. Depending on the size and structure of the workpiece, the quenching strength can be adjusted by adjusting the fan speed and quenching pressure. Recently, it has been found that there is a phenomenon of local whitening on the surface of the workpiece after heat treatment. Each furnace of whitened workpieces is concentrated at both ends of the tooling, with a certain regularity. Usually, the surface of the workpiece after vacuum carburizing, high-pressure gas quenching, and low-temperature tempering is light yellow. In order to find out the reason for the whitening of the workpiece and ensure its quality, metallographic structure observation and hardness testing are performed on the whitened parts.

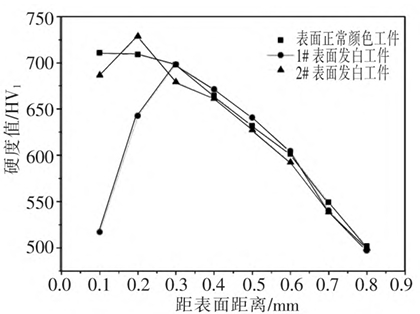

The surface hardness distribution curve of the gear workpiece after heat treatment. The quenching temperature for workpiece 1# is 950℃, and for workpiece 2# it is 870℃.

For gear workpieces with normal surface color, the hardness gradually decreases with increasing distance from the surface, and the rate of hardness reduction is less than 40HV1/0.1mm. The hardness at a distance of 0.05mm from the surface is 710.5HV1, which is converted to a Rockwell hardness of 60.2HRC, meeting the technical requirements. From the hardness curve of workpiece 1#, it can be seen that when the distance from the surface is not greater than 0.2mm, the hardness value is between 505 and 640HV1, which is far below the technical requirement value of 660 to 750HV1; when the distance from the surface is greater than 0.2mm, the hardness distribution closely follows the trend of hardness distribution of workpieces with normal surface color. Therefore, it can be seen that the hardness of the whitened part is lower than the normal value only in a very shallow region near the surface, which is known as the “lowering phenomenon”. From the hardness curve of workpiece 2#, it can be seen that when the distance from the surface is not greater than 0.1mm, there is a lowering phenomenon in hardness; when the distance from the surface is greater than 0.1mm, the hardness distribution shows a normal hardness gradient.

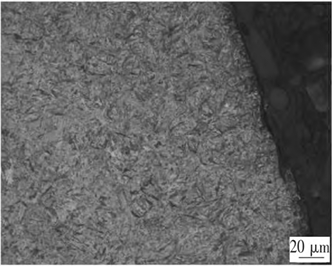

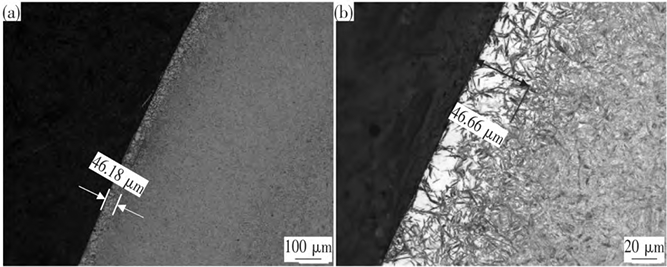

The metallographic structure of the 20CrMnTiH gear after heat treatment was observed using a Zeiss AxioVert.A1 optical microscope. The surface color of the normal workpiece was a small amount of retained austenite and tempered martensite, which was rated as Level 1 according to the standard GB/T 25744 and met the technical requirements. The metallographic structure of the white part of the gear workpiece after quenching treatment. The white surface layer had a clear boundary with the inner layer, and the residual austenite layer depth was about 46 μm. The white layer was a coarse residual austenite structure, which was rated as Level 6 or above according to the standard, which was seriously out of tolerance.

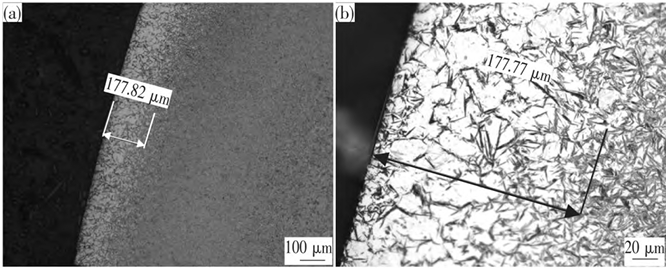

The metallographic structure of the white part of the 20CrMnTiH gear workpiece after quenching. The white layer on the surface has a clear boundary with the inner layer, with a depth of about 179 μm, which is much deeper than the white layer on the surface of the 870 ℃ quenched workpiece. It can be seen that the ability of vacuum carburizing workpieces to absorb active carbon atoms at high temperatures is much higher than that at low temperatures, which is also the main reason for the shorter carburizing time at high temperatures and low pressures under the same hardened layer depth requirements. The white layer on the surface of the gear workpiece is a coarse residual austenite structure, and there are large-sized carbides on the surface, which are rated as above level 6 according to the standard, which is seriously out of tolerance. The amount of residual austenite can reflect the hardness of the material, and the metallographic examination of the residual austenite layer depth distribution coincides with the hardness curve shown in Figure 2. It can be seen that the low surface hardness of the white part of the workpiece is mainly caused by excessive residual austenite in the surface layer. Generally, single-phase austenite has higher corrosion resistance than tempered martensite, and the presence of a large amount of residual austenite on the surface of the workpiece leads to higher corrosion resistance and oxidation resistance in these areas than in normal metallographic structures, resulting in white phenomena after tempering in these areas.

Analysis and Discussion on Abnormalities in the Production Process of Gears

Through multi-furnace observation of the whitening position of the 20CrMnTiH gear workpiece, it was found that the whitening part of the workpiece was facing the outside of the tooling. The excessive saturation carbon concentration was caused by excessive residual austenite in the gear tooth tip and tooth surface. In order to find out the reason for the excessive carbon concentration in the local surface of the product at both ends of the tooling, we analyzed the process parameters and the recording curves of the carburizing and quenching process of the relevant furnaces and found no abnormalities. It is speculated that the equipment may be the cause of the local whitening of the product. The workpiece enters and exits the heating chamber through a transfer car in the transfer channel, which is equipped with a heat shield with open ends at both ends. After the carburizing process is completed, the internal transfer car automatically opens and moves to the corresponding heating chamber to remove the workpiece, and then transfers it to the gas quenching chamber. Due to the different distances between each heating chamber and the gas quenching chamber, the transfer time takes 9-12 seconds. Leakage detection was performed on the acetylene process pipeline between the inner lining and the water-cooled wall of the heating chamber, and multiple leakage points were found. When multiple heating chambers are working, acetylene enters the transfer channel through the leakage points before entering the heating chamber. Due to the pressure and temperature inside the channel being lower than those in the heating chamber, the leaked acetylene accumulates in the channel. Due to the accumulation of acetylene in the channel, the workpiece at both ends of the tooling first comes into contact with the accumulated acetylene in the channel during the transfer process after exiting the furnace, and the high-temperature workpiece adsorbs acetylene-decomposed active carbon atoms on its surface, resulting in secondary strong carburization in a short period of time. Due to the high quenching temperature, the highly saturated carbon in the surface layer causes a large amount of residual austenite, which is also the reason for the obvious boundary between the residual austenite layer and the subsurface normal structure shown in Figures 4 and 5, rather than a gradual change trend with increasing depth. The presence of a large amount of residual austenite on the surface layer of the workpiece leads to a decrease in hardness of the tooth surface The contact fatigue strength of the low and gears decreases. A large amount of residual austenite is generated on the tooth surface, which is thermally and abrasively processed during grinding The transformation under the action of cutting force leads to grinding cracks on the tooth surface, causing significant quality risks. Therefore, in order to ensure product quality and avoid the risk of It is particularly necessary for alkynes to leak into the transfer channel through pipelines. Through repairing the acetylene leakage point and observing multiple furnace production cycles, no white discoloration was found

Metallographic observation and hardness testing of the workpieces at both ends of the tooling also revealed no abnormalities, ensuring product quality and reducing scrap rates, and create good economic benefits for the enterprise.

Gear conclusions and suggestions

After secondary carburizing and quenching, a large amount of residual austenite is generated on the surface of the 20CrMnTiH gear workpiece, which is the main reason for its local whitening and low surface hardness. Through leak detection and repair of the equipment’s acetylene pipeline interface, more acetylene leakage into the transfer channel was avoided, and the problem of excessive residual austenite on the surface of the workpiece after quenching was solved.