Introduction

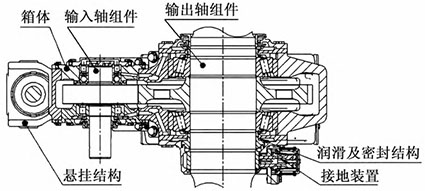

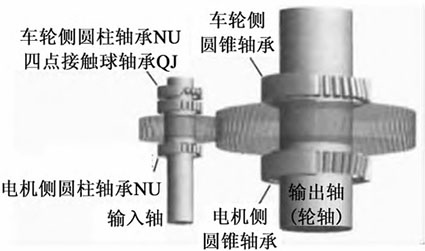

The G321 gearbox is used for the assembly of the bullet train. The schematic diagram of the gearbox structure is shown in Figure 1. The pinion shaft motor side of the gearbox is equipped with cylindrical roller bearings, which bear radial loads. The wheel side of the pinion shaft uses cylindrical roller bearings and four-point contact ball bearings, which also bear radial loads. The cylindrical roller bearings are installed into the bearing seat by interference fit. The four-point contact ball bearing inner ring is fixed by the pinion shaft gland, and the four-point contact ball bearing outer ring is fixed by the sealing cover. The standard bullet train unit requires an advanced repair every 1.2 million kilometers of operation, and the advanced repair sequence is three-level repair → four-level repair → three-level repair → five-level repair. This failure occurred in the gearbox The following focuses on the maintenance content of the fourth-level repair of the gearbox: During the fourth-level repair of the gearbox, it is necessary to disassemble the gearbox and divide it into The gearbox is disassembled to the minimum component state, and the large gear shaft and small gear shaft side bearings of the gearbox are replaced. The bearing caps, collector rings, sealing covers, large gears, small gears, and various bolt seats are disassembled for maintenance. The large and small gears are inspected for defects. After completing the maintenance of the above components, the gearbox is reassembled. After reassembling the gearbox, it is necessary to measure the bearing clearance of the large gear shaft, the bearing clearance of the small gear shaft, and the tooth clearance of the large and small gears. The standard EMU column pinion shaft motor side (PM side) uses cylindrical bearings, and the pinion shaft wheel side (PW side) uses a cylindrical bearing plus a ball bearing structure. This structure determines the gear The clearance of the pinion shaft after the gearbox is assembled depends on the assembly clearance of the ball bearing. In theory, the clearance should be a stable value after the gearbox is assembled The clearance value should not change; in order to ensure the assembly of the gearbox is qualified, it is required to conduct a clearance measurement on the pinion shaft bearing after the assembly of the gearbox is completed After the running-in test in the gearbox, the clearance of the pinion shaft bearing is measured twice, with the requirement that the two measurements have a small change and both are full Standard requirements for the clearance of the foot pinion shaft.

Process flow

To facilitate the understanding of this article, the assembly of the pinion shaft is now described The process flow and some terms are explained.

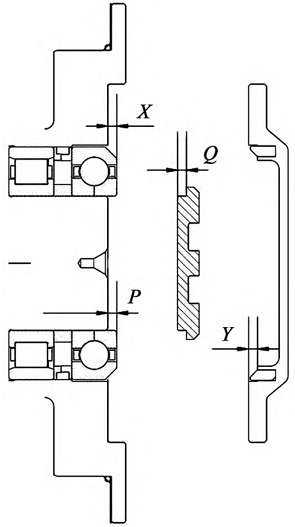

During the assembly of the pinion, it is necessary to measure four values, including the bearing pressure plate and the sealing covers X, Y, P, and Q on the PW side, to ensure that the inner and outer rings of the ball bearing are compressed. The actual significance of these four values is shown in the figure. The clearance of the pinion shaft bearing of the standard EMU trainset needs to meet the standard requirements; the X-Y difference range and the P-Q difference range need to meet the requirements.

Fault phenomenon

During the Level 4 repair of the M2 vehicle’s 1st axle, the new pinion side bearing was replaced with a new one. The box number is 0000. After assembly, the clearance was measured on the vertical assembly station After running-in, the clearance measurement on the flat-packing station was not qualified. The M2 vehicle has a 4-axis, and during the Level 4 repair, the new pinion side bearing was replaced. The box number is 1111. After assembly, the clearance measurement on the vertical station was qualified, but after running-in, the clearance measurement on the flat-packing station was not qualified. The M3 vehicle has a 1-axis, and during the Level 4 repair, the new pinion side bearing was replaced. The box number is 1112. After assembly, the clearance measurement on the vertical station was not qualified. After disassembling the PW side bearing gland and reassembling it, the clearance measurement on the vertical station was qualified. The gearbox (1111) was lifted to the flat-packing station for clearance measurement. The clearance measurement was not qualified. The PW side bearing gland was impacted, and the clearance measurement was qualified. The pinion shaft M side was impacted, and the clearance measurement was qualified. Through the above-mentioned failures, it can be seen that the clearance on the pinion shaft side is greatly affected by the running-in test and the reassembly of the sealing cover, and the clearance value is unstable. Therefore, the following tests were conducted.

Experimental verification

The clearance of the pinion shaft bearing is determined by a four-point contact ball bearing, which has an inner ring divided into A and B sides, and a four-point contact ball shaft The inner ring and the pinion shaft are interference fit, and the inner ring is assembled onto the pinion shaft after being heated and expanded. The bearing press plate is bolted to the pinion The axle is connected to fix the inner ring of the four-point contact ball bearing, and the outer ring of the four-point contact ball bearing is fixed in the axial direction by the outer spacer ring and the sealing cover. The instability of the bearing clearance is closely related to the assembly of the above components, and the following tentative tests are proposed: 1) study the difference in measuring the clearance of the pinion shaft under the flat and vertical mounting positions; 2) study the influence of the deflection of the spacer ring on the bearing clearance; 3) study the relationship between the change in radial position of the outer ring of the four-point contact ball bearing and the change in bearing clearance; 4) study the relationship between the assembly of the sealing cover and the change in bearing clearance.

When measuring the clearance of the pinion shaft bearing under the flat and vertical mounting positions, the force used during the measurement process is consistent. However, due to the need to overcome the gravity of the pinion shaft itself when using the vertical mounting position, while there is no need to overcome the gravity of the pinion shaft itself when using the flat mounting position, it is necessary to verify the impact of this condition on the clearance of the pinion shaft bearing. The gearbox (0000) is lifted to the flat mounting position for clearance measurement, and the clearance value is A; when lifted to the vertical mounting position for clearance measurement, the clearance value is A + 0.001. The gearbox (1111) is lifted to the flat mounting position for clearance measurement, and the clearance value is B; when lifted to the vertical mounting position for clearance measurement, the clearance value is B – 0.001. The gearbox is measured for clearance of the pinion shaft bearing under both flat and vertical mounting conditions. The results show that the flat and vertical mounting positions do not affect the clearance of the pinion shaft bearing. Based on the results of this experiment, the following conclusions can be drawn: when the gearbox is in the vertical or flat mounting state, there is essentially no change in the clearance of the pinion shaft of the gearbox, and whether the gearbox is mounted in a flat or vertical state is not a key factor affecting the change in clearance of the pinion shaft.

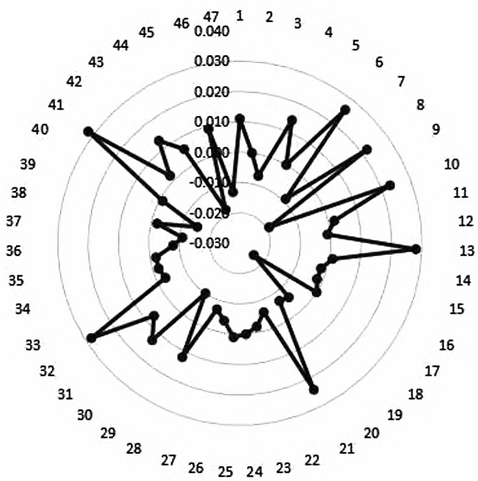

Result analysis

When the outer ring of a four-point contact ball bearing is initially installed, the bearing outer ring will move radially, causing the outer ring and inner ring to be misaligned. Excessive displacement can affect the Bearing clearance, at this time, install the sealing cover, and compress the outer ring of the bearing with the sealing cover; if the press-fit force is sufficient, the clearance is relatively stable, and the clearance value may not be consistent After running-in, the expansion force is not enough to overcome the pressure provided by the outer ring, and the self-adjustment of the bearing outer ring cannot be carried out. The clearance after running-in is not qualified; if the pressure The assembly force is insufficient, and the expansion force after running-in is sufficient to overcome the pressure provided by the outer ring. The bearing outer ring can be self-adjusted, and the bearing outer ring is concentric with the bearing inner ring, running-in The clearance may change; when the outer ring and inner ring of the four-point contact ball bearing are eccentric, the effect of the sealing cover causes the four-point contact ball bearing rollers and shafts to

There is a radial additional force on the outer ring, which indirectly limits the clearance of the four-point contact ball bearing. When disassembling the sealing cover, the outer ring of the bearing is in contact with the rolling The additional force between the sub-elements is released, and the outer ring returns to a relatively ideal position. At this time, the sealing cover is assembled again, and the clearance value is more stable. According to the radial clearance calculation formula for four-point contact ball bearings: Gr = 2DWCosβ, it can be seen that the contact angle β between the steel ball and the inner and outer rings of the bearing affects the size of the clearance value of the four-point contact ball bearing. The schematic diagram is shown in the figure. Whether the outer ring and inner ring of the four-point contact ball bearing are concentric will lead to changes in the angle β, which directly affects the size of the bearing clearance. Therefore, it can be seen that the assembly quality will affect the contact angle between the roller and the inner and outer rings of the four-point contact ball bearing. Given that the inner ring of the bearing is fixed and the outer ring of the bearing is in a free state, how to make the outer ring of the bearing concentric with the inner ring of the bearing and ensure the stability of the angle β is the key to ensuring the bearing clearance.

Epilogue

By addressing abnormal issues during the advanced repair process of the bullet train, improving the assembly process of the gearbox, and promoting the improvement of the new manufacturing process of the bullet train, the quality of the entire vehicle product can be improved. As the mileage of the bullet train increases, parts gradually enter advanced repair, and data statistics of the parts during the maintenance process should be collected. Using data and faults as a driving force, the quality of manufacturing and repair can be effectively improved.