Introduction

Beveloid gears are a unique type of gears that have found applications in various mechanical systems. They possess characteristics that make them distinct from traditional bevel gears and other gear types. This article aims to provide a comprehensive understanding of beveloid gears, covering their structure, working principles, advantages, disadvantages, manufacturing processes, and applications.

Definition and Basic Structure

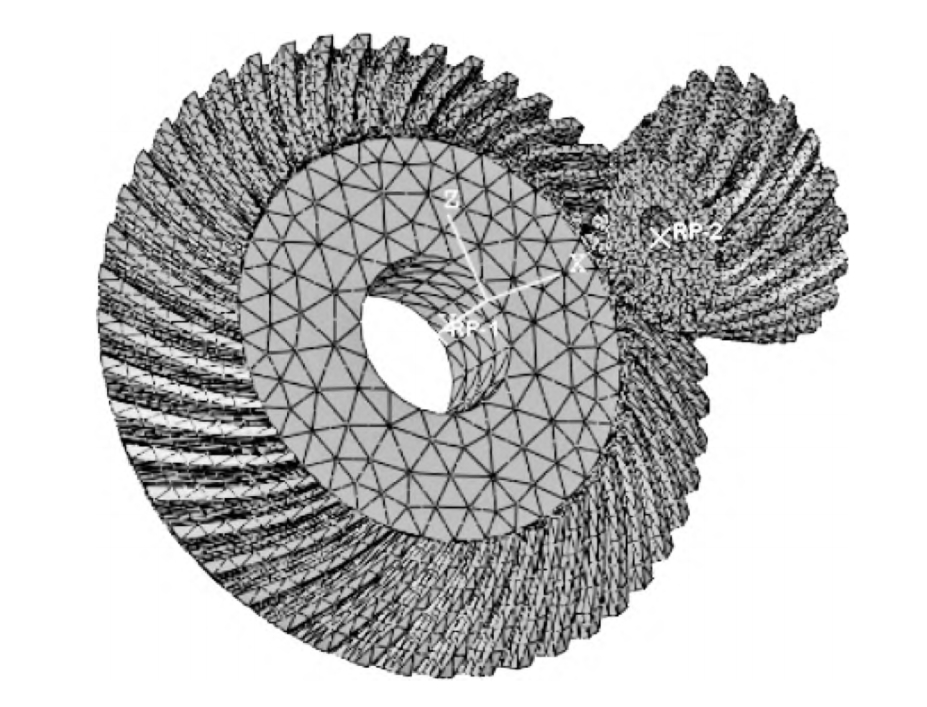

A beveloid gear is a type of gear that has a conical shape with a non – uniform tooth thickness along the axial direction. Unlike a standard bevel gear where the teeth have a constant cross – sectional shape throughout the gear, beveloid gears have a more complex geometry. The teeth of a beveloid gear can be thought of as being 扭曲 or tapered in a specific way to achieve certain mechanical functions.

| Comparison with Bevel Gears | Beveloid Gears | Bevel Gears |

|---|---|---|

| Tooth Thickness Variation | Varies along the axis | Generally constant |

| Conical Shape Complexity | More complex | Standard conical |

Working Principles

The operation of beveloid gears involves the meshing of two or more gears with their conical surfaces in contact. When the gears rotate, the teeth engage and transfer torque from the driving gear to the driven gear. The unique geometry of beveloid gears allows for a more gradual transfer of load compared to some other gear types. This is due to the varying tooth thickness, which can be designed to optimize the load distribution during the meshing process.

- As the gears rotate, the contact points between the teeth move along the tooth surfaces. In beveloid gears, this movement is carefully controlled by the design of the tooth geometry to ensure smooth and efficient power transmission.

- The angle at which the beveloid gears are mounted and the orientation of their axes also play a crucial role in determining the direction and magnitude of the transmitted torque.

Advantages of Beveloid Gears

Improved Load Distribution

The non – uniform tooth thickness of beveloid gears enables better load sharing among the teeth. This results in reduced stress concentrations on individual teeth, thereby increasing the overall durability and load – carrying capacity of the gear set.

| Gear Type | Load Distribution Efficiency |

|---|---|

| Beveloid Gears | High |

| Standard Spur Gears | Moderate |

Compact Design

Beveloid gears can often achieve the same gear ratio as other types of gears in a more compact space. This is particularly advantageous in applications where space is limited, such as in some small mechanical devices or in the design of compact transmissions.

Noise and Vibration Reduction

The smooth engagement of the teeth in beveloid gears, due to their carefully designed geometry, leads to lower noise and vibration levels during operation. This is beneficial in applications where noise and vibration can cause problems, such as in precision machinery or in environments where quiet operation is required.