Introduction

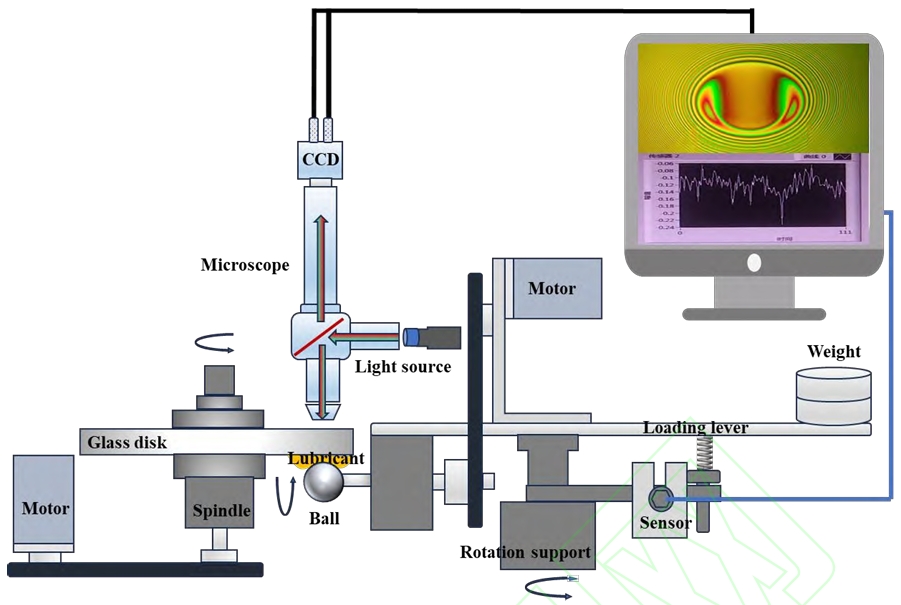

With the increasing demand for energy and environmental protection, as well as the special properties of synthetic oil, synthetic oil plays an important role in engineering. More and more wind turbine manufacturers and operators have recognized the benefits of synthetic gear oil and replaced mineral oil with synthetic oil with good comprehensive performance. The synthetic oil currently used in wind power gearbox lubricants is mainly PAO (polyalphaolefin), followed by PAG (polyether). The most commonly specified gear oil viscosity grade for wind turbine manufacturers is ISO, and the selection of gear oil is based on the performance required for wind power gearbox lubricants, taking into account the impact of oil on the gearbox bearings. The rolling bearings in the gearbox work by generating very high local contact pressures between components, which requires elastic fluid dynamic lubrication as the main lubrication mechanism. The input end bearings of the main gearbox require high viscosity and high load capacity lubricants, while the output end bearings require low viscosity and good shear resistance lubricants. The service life and efficiency of rolling bearings are closely related to the oil film lubrication state and rheological properties of lubricants in wind power gearboxes. Many researchers at home and abroad have conducted extensive research on the rheological properties of lubricants under high-pressure rolling contact conditions, and have also conducted extensive research on different types of lubricants. However, there is relatively little research on the rheological properties and lubrication performance comparison between different types of lubricants, especially for wind power gearbox lubricants. In this experiment, three types of wind power gearbox lubricants, PG320 (PAG), UNISYN CLP320 (PAO), and mineral oil CLP320, were used as the research objects. A ball-point contact light interference lubricant film and friction force measurement device were used to simultaneously measure the oil film thickness and friction coefficient of the three lubricants. The pressure-viscosity coefficient of the lubricant was determined using light interference method to analyze the rheological properties and lubrication performance of the three lubricants, providing a reference for the selection of lubricants for wind power gearboxes.

conclusion

(1) The pressure-viscosity coefficient values of mineral oil, PAO oil, and PAG oil were measured, providing a theoretical basis for studying gear oil for wind turbines

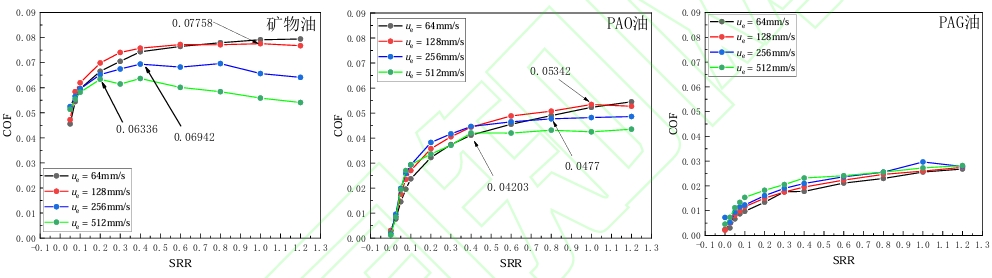

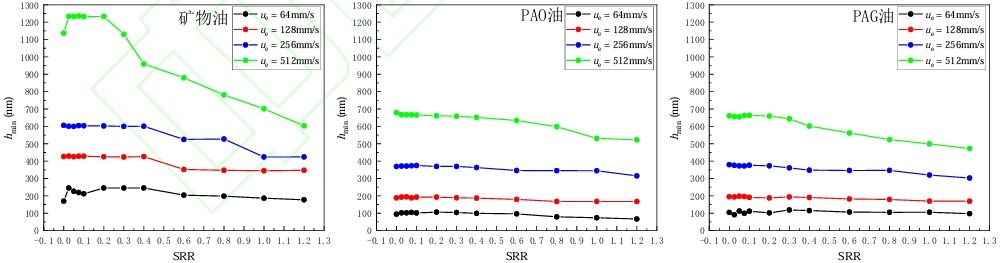

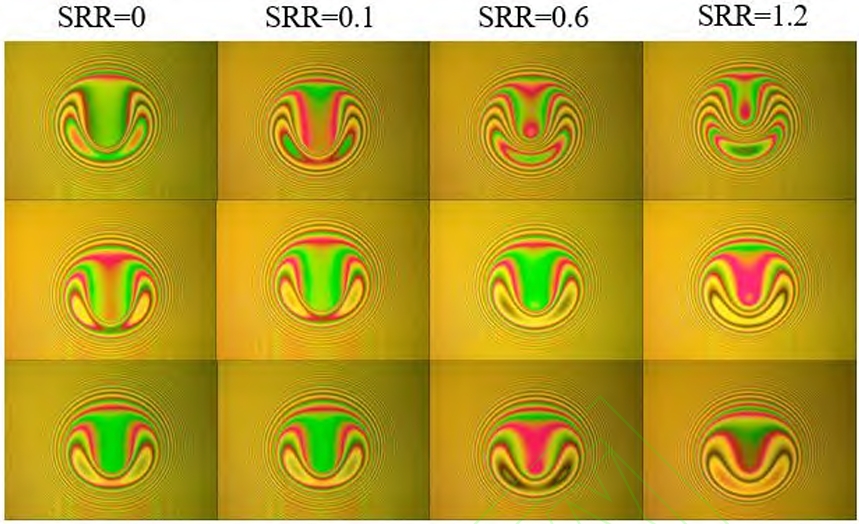

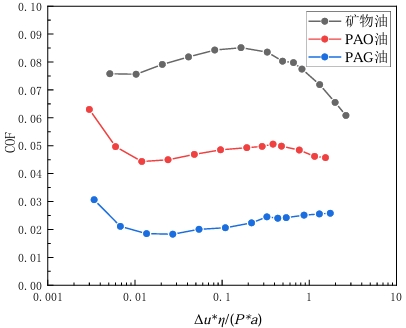

(2) Mineral oil enters the shear thinning effect region relatively quickly and reaches the limit shear stress. As the shear increases, the friction coefficient is greatly affected and the friction coefficient is high. Mineral oil has a greater response to thermal effects compared to PAO oil and PAG oil. PAG oil has almost no limit shear stress stage at low loads, with better shear performance and a low friction coefficient

(3) The lubricating performance of PAG synthetic oil is superior to that of PAO synthetic oil. Mineral oil has the worst lubricating performance.